By Jitendra Srivastava

Step inside any modern aircraft assembly facility and you’ll notice something different. The structure of the aerospace supply chain is quietly evolving. What was once a predictable hierarchy, Tier-1 to Tier-2 to Tier-3, is now far more interconnected.

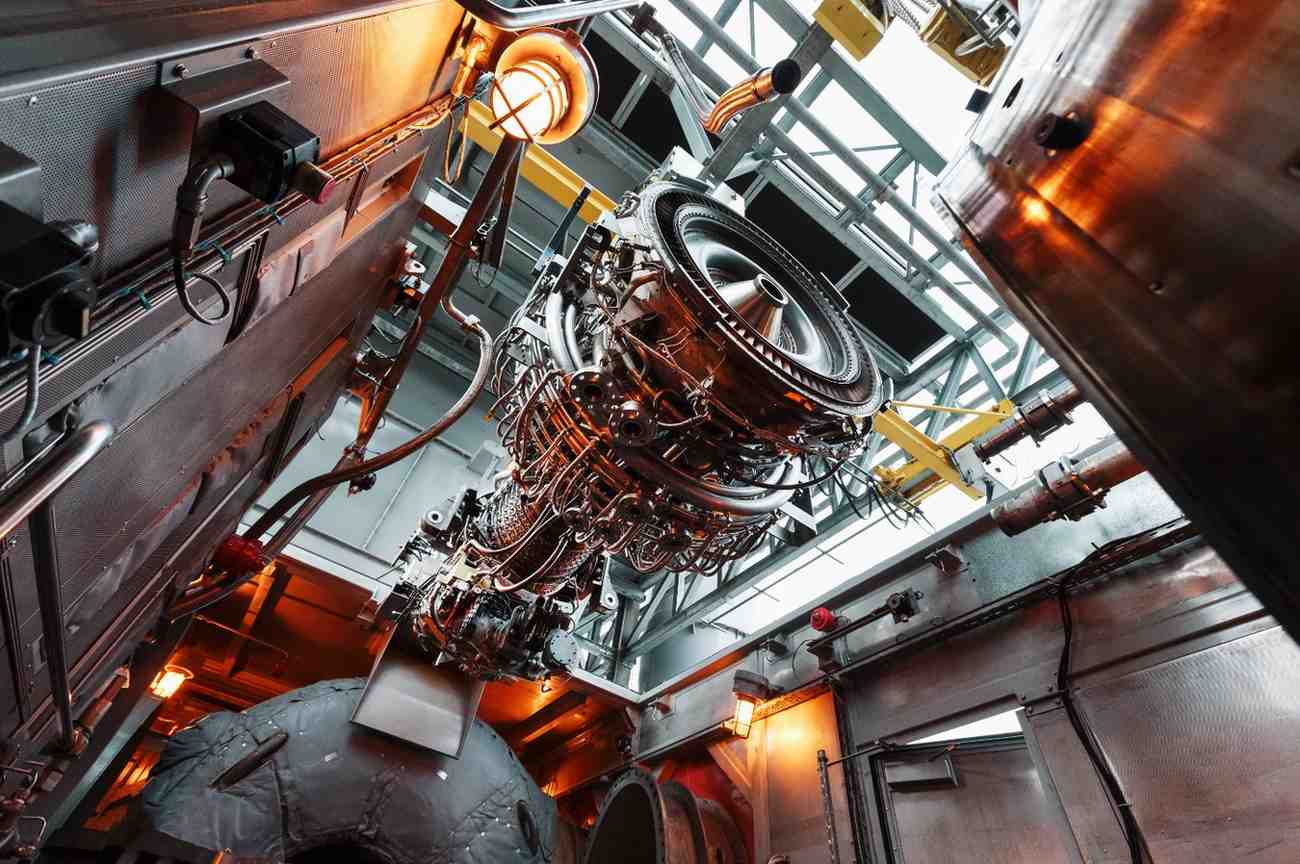

Aerospace OEMs are building closer relationships with Tier-3 vendors, the specialized manufacturers producing precision components such as fasteners, wiring harnesses, seals, castings, and electronic subassemblies.

This shift is not a trend. It is a response to disruption, cost pressures, and the need for resilience.

A Supply Chain Under Pressure

The aerospace sector has experienced significant volatility in recent years. According to the Government of India’s Ministry of Civil Aviation, India alone handled over 150 million domestic passengers in FY 2023–24, marking a full recovery and growth beyond pre-pandemic levels. Increased aircraft demand places enormous pressure on global production ecosystems.

Similarly, the U.S. Bureau of Transportation Statistics (BTS) reports that U.S. airlines carried over 850 million passengers in 2023, highlighting the scale at which aircraft manufacturing must operate.

As aircraft production ramps up worldwide, OEMs are re-evaluating how their supply chain functions. Concentrated sourcing models relying heavily on a limited number of large suppliers proved vulnerable during global disruptions. Production delays, container shortages, and geopolitical constraints exposed structural weaknesses.

The result? A deliberate move toward diversification and deeper engagement with Tier-3 suppliers.

Why Tier-3 Vendors Matter More Than Ever

Tier-3 vendors were once several layers removed from OEM decision-making. Today, they are becoming strategic contributors.

There are three main reasons behind this evolution:

- Modular Manufacturing

Aircraft platforms are increasingly modular. Specialized vendors can develop highly engineered sub-components independently, allowing OEMs to test innovations faster and reduce single-source dependency. - Regional Ecosystem Growth

Governments worldwideare investing in aerospace manufacturing clusters. India’s aerospace and defence production crossed ₹1 lakh crore in FY 2022–23, according to the Government of India, Ministry of Defence. Similar industrial expansion is visible across Eastern Europe and Southeast Asia.

This distributed growth strengthens Tier-3 ecosystems and encourages localized sourcing.

- Risk Diversification

Working directly with multiple smaller vendors spreads production risk and improves responsiveness. Instead of relying on one dominant supplier, OEMs gain flexibility across geographies.

But as supplier networks expand, the complexity of coordination increases exponentially. That’s where logistics solutions

become mission-critical.

The Growing Importance of Ground Logistics

In aerospace manufacturing, precision extends beyond engineering, it applies equally to logistics.

Components may be machined in Poland, assembled in Malaysia, coated in Germany, and integrated in Toulouse. Each shipment must comply with strict aerospace standards covering packaging, shock resistance, temperature control, and documentation.

While air freight remains essential for urgent movements, ground logistics is increasingly becoming the backbone of the aerospace supply chain.

Road and rail transport offer:

- Greater handling control for sensitive or oversized components

- Lower cost compared to air freight

- Reduced carbon emissions

- Flexible routing between consolidation hubs and assembly plants

According to the U.S. Department of Transportation, freight rail can move one ton of cargo over 470 miles on a single gallon of fuel demonstrating why multimodal planning is central to cost-efficient and sustainable logistics strategies.

For aerospace OEMs balancing cost, speed, and compliance, integrating ground logistics into broader logistics solutions creates stability without sacrificing performance.

Regional Consolidation Hubs: A Structural Shift

As supplier bases expand, regional consolidation hubs are emerging as coordination centers.

These hubs receive components from multiple Tier-3 vendors, conduct quality checks, manage documentation, and prepare consolidated shipments for final assembly. This approach reduces congestion at main manufacturing facilities and enables proactive quality control.

For OEMs, this means:

- Shorter assembly line interruptions

- Improved inventory visibility

- Reduced administrative burden

- Faster customs clearance

The aerospace supply chain is no longer linear, it is a synchronized network. Effective orchestration is becoming more valuable than scale alone.

Technology: The Visibility Imperative

A distributed supply chain cannot function without real-time data.

Digital logistics platforms now allow OEMs, suppliers, and logistics partners to track shipments simultaneously. Predictive alerts identify potential delays before they impact production schedules. Automated compliance documentation reduces manual errors.

In a sector where production delays can cost millions per day, visibility is no longer optional, it is foundational to resilience.

At Triton, we see technology as the connective tissue of modern logistics solutions. Integrated dashboards across air, sea, and ground logistics enable faster decision-making and tighter coordination between stakeholders.

Sustainability Is No Longer Secondary

Sustainability is reshaping aerospace operations. Governments worldwide are setting aggressive emissions reduction targets. Smarter supply chain design especially through optimized ground logistics helps reduce dependency on high-emission air freight where not critical.

Combining regional sourcing, multimodal transport, and improved load utilization creates measurable efficiency gains. Responsible logistics is not a marketing message; it is becoming a contractual and regulatory requirement.

The Path Forward

The aerospace supply chain is entering a new era more distributed, more digital, and more resilient.

Tier-3 vendors are no longer hidden layers in the background. They are strategic partners in innovation and risk management. But unlocking their full value requires intelligent logistics solutions capable of managing complexity without compromising control.

For OEMs, the question is no longer whether to diversify but how to connect every moving part seamlessly.

At Triton, we believe ground logistics, integrated technology, and compliance-driven execution form the foundation of that future.

Because in aerospace, precision doesn’t end at manufacturing. It continues across every mile of the supply chain.

FAQs

1. Why are aerospace OEMs restructuring their supply chain models?

Aerospace OEMs are restructuring their supply chain to improve resilience, flexibility, and cost efficiency. Over the past few years, global disruptions exposed the risks of concentrated sourcing models that depended heavily on a limited number of Tier-1 suppliers. Delays in raw materials, shipping bottlenecks, and geopolitical uncertainties created cascading production slowdowns.

By engaging more directly with Tier-3 vendors who manufacture precision components such as fasteners, wiring harnesses, machined parts, and electronic subassemblies—OEMs can diversify sourcing, reduce single-point dependency, and strengthen regional manufacturing ecosystems. This distributed supply chain model increases adaptability while maintaining quality standards. However, it also requires more advanced logistics solutions to coordinate multiple suppliers across regions.

2. What role do Tier-3 vendors play in the modern aerospace industry?

Tier-3 vendors specialize in highly engineered, small but critical components that form the foundation of aircraft systems. While they may not assemble large structures like fuselages or engines, their products directly impact safety, performance, and regulatory compliance.

As aircraft designs become more modular and technologically advanced, the importance of these specialized suppliers has grown. OEMs increasingly collaborate directly with Tier-3 manufacturers to drive innovation, improve quality oversight, and accelerate production timelines. This shift elevates Tier-3 vendors from being indirect contributors to becoming strategic partners within the aerospace supply chain.

3. How does ground logistics improve efficiency in aerospace manufacturing?

Ground logistics plays a central role in improving both operational control and cost management within the aerospace supply chain. While air freight is essential for urgent shipments, road and rail transport offer greater flexibility and handling precision for sensitive or oversized components.

Ground transportation enables controlled movement with reduced vibration, better temperature management options, and lower overall transport costs. It also supports regional consolidation hubs, where parts from multiple Tier-3 vendors are inspected, documented, and prepared for final assembly delivery.

By integrating ground logistics into broader multimodal logistics solutions, aerospace companies can balance speed with cost efficiency, reduce carbon emissions, and maintain tighter shipment visibility across regions.

4. Why are regional consolidation hubs becoming critical in aerospace logistics?

As supplier networks expand across countries and continents, regional consolidation hubs act as coordination centers within the supply chain. These hubs collect components from multiple Tier-3 vendors, perform quality checks, manage documentation, and consolidate shipments before forwarding them to final assembly plants.

This model reduces congestion at primary manufacturing facilities and ensures that parts arrive in synchronized batches aligned with production schedules. It also strengthens compliance by centralizing customs documentation and inspection processes closer to the source.

In a highly regulated industry like aerospace—where delays can disrupt entire assembly lines—regional hubs provide structured control, enhanced visibility, and improved supply chain orchestration.

5. How is technology transforming aerospace supply chain visibility and resilience?

Technology has become the backbone of modern aerospace logistics solutions. With supply chains spanning multiple countries, real-time visibility is essential for preventing disruptions and maintaining production continuity.

Advanced digital platforms now allow OEMs, suppliers, and logistics providers to monitor shipments simultaneously. Predictive tracking systems identify potential delays before they impact assembly schedules. Automated compliance documentation minimizes administrative errors, while integrated dashboards combine air, sea, and ground logistics data into a single view.

This level of transparency improves decision-making speed, enhances risk management, and builds trust across the supply chain. In an industry where precision and timing are critical, digital connectivity ensures that every component moves with accountability and control.