By Jitendra Srivastava

In aerospace, speed makes headlines. Precision keeps programs alive.

When you are moving a jet engine, a fuselage section, or a wing assembly, you are not shipping cargo. You are relocating months of engineering effort. One improper tilt, one vibration spike, one clearance miscalculation can undo it all. That is why, even in 2025, ground transport remains central to aerospace logistics.

Let’s look at the bigger picture first.

India’s aviation ecosystem is expanding rapidly. The Ministry of Civil Aviation has consistently reported strong passenger growth and fleet expansion in its annual reviews. At the same time, the Ministry of Defence continues to emphasize domestic defense manufacturing and indigenization. Add to this the increasing private participation encouraged by the Indian Space Research Organisation, and you have a clear trend: more aerospace components are being built, tested, and integrated across multiple Indian locations.

More manufacturing activity means more movement. And much of that movement happens through ground transportation.

The Reality of Aerospace Dimensions

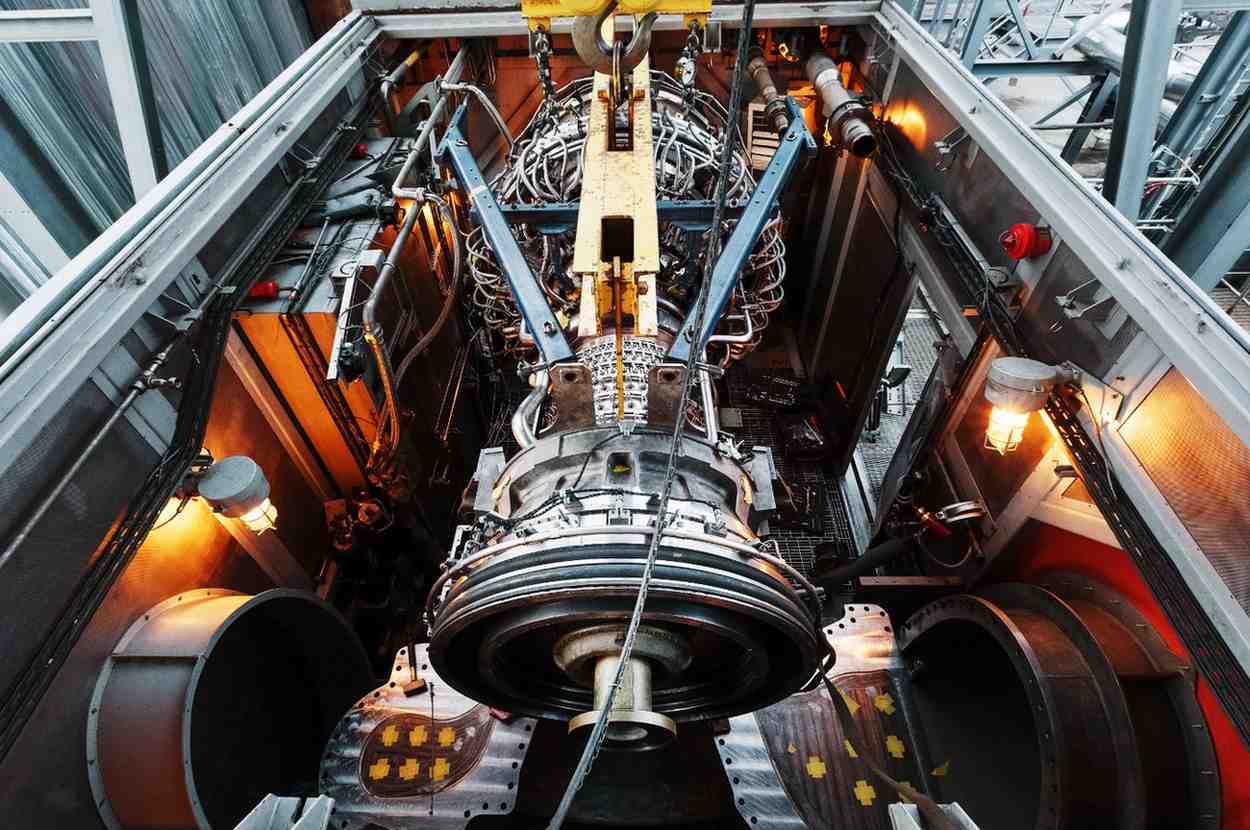

Aerospace cargo rarely fits standard molds. Engines can weigh several tonnes. Fuselage barrels stretch across dozens of meters. Composite structures have irregular geometry and sensitive internal tolerances.

Air transport may be fast, but it comes with constraints: door dimensions, aircraft payload limits, airport infrastructure, loading angles, and cost. For many oversized or heavy components, ground transport is not a backup option. It is the primary route.

Ground transportation allows full control over loading configuration, weight distribution, and securing methods. Every detail can be engineered before the first wheel turns.

Why Control Matters More Than Speed

Here’s the thing. A micro-fracture in a composite panel or misalignment in an engine mount can delay installation, trigger inspection cycles, or even force re-certification. The financial impact of that kind of damage far outweighs the benefit of shaving a few hours off transit time.

Ground transport enables slow, controlled movement with engineered cradles, hydraulic suspension systems, and multi-axle trailers that distribute load evenly. Rail, where available, provides a stable platform for long-distance movement with reduced high-frequency vibration.

For aerospace manufacturers, this precision-first approach protects schedule integrity. For a logistics service provider, it transforms transportation into a technical responsibility rather than a basic shipment.

Engineering the Route, Not Just the Vehicle

Oversized aerospace loads require more than a trailer booking. They require route engineering.

Bridge load capacity, turning radius, overhead cable clearance, gradient angles, and traffic density all matter. Special permits, police escorts, and utility coordination are often mandatory. The Ministry of Road Transport and Highways, Government of India regulates vehicle dimensions and weight norms, and compliance is non-negotiable.

Ground transportation gives planners the flexibility to conduct route surveys, simulate movement, and create contingency plans. That level of control is difficult to replicate in air-based solutions.

In aerospace logistics, predictability is power.

Shock and Vibration Management

Modern ground logistics integrates sensor-based monitoring. Acceleration, tilt, and temperature data can be recorded throughout the journey. If vibration exceeds predefined limits, corrective action can be taken.

Rail movement, particularly over long corridors, offers smoother motion profiles compared to some other modes. When paired with specialized road trailers for first-mile and last-mile legs, the result is a controlled, traceable chain of custody.

This combination of rail and road ground transport forms a balanced ground logistics strategy that protects component integrity.

Ground Transport and Sustainability

Sustainability is now a board-level priority. According to government transport assessments, rail remains more energy efficient per ton-kilometer compared to air. When schedules allow, integrating rail within ground transportation frameworks can reduce environmental impact while maintaining safety and reliability.

For aerospace manufacturers increasingly accountable for environmental performance, this matters. A well-designed ground logistics plan supports both operational and sustainability objectives.

Integrated Logistics Service Model

Moving aerospace cargo is not a transactional job. It is a project.

A complete logistics solution includes feasibility studies, structural fixture design, permit management, escort coordination, insurance alignment, documentation control, loading supervision, and final inspection at destination.

Ground transportation enables this integrated oversight. The same team can manage cradle design, supervise loading, coordinate escort vehicles, and monitor real-time movement. That continuity reduces handoffs and lowers risk.

A strong logistics service provider in aerospace understands that the movement begins long before the vehicle departs and ends only when the part is ready for installation.

Why Ground Logistics Leads in 2025

Even as specialized cargo aircraft evolve, limitations remain: airport access, runway constraints, heavy-lift scheduling, and high cost structures. Ground transport offers flexibility in routing, access to manufacturing clusters, and direct plant-to-plant delivery.

For many aerospace manufacturers, ground logistics is not about compromise. It is about responsibility.

When you are moving a wing section ready for assembly or an engine prepared for integration, the priority is not arrival time alone. It is arrival condition.

Our Approach at Triton

At Triton Logistics & Maritime, we treat aerospace ground transport as an engineering assignment. Our teams plan routes in coordination with regulatory authorities, design custom fixtures, integrate vibration-monitoring systems, and manage every permit required for compliant movement.

We do not separate transport from technical understanding. Our logistics solution integrates structural planning, escort coordination, documentation accuracy, and real-time oversight.

When urgency demands speed, we act decisively. But when precision defines success, we rely on engineered ground transportation.

Because in aerospace, the cost of getting it wrong is far greater than the benefit of moving fast.

FAQs

1. Why is ground transport preferred for large aerospace components?

Ground transport is preferred for large aerospace components because it offers maximum physical control over handling, loading, and route execution.

Aircraft fuselage sections, wing assemblies, landing gear systems, and engine casings often exceed standard cargo dimensions. Moving these by road allows for customized trailer configurations, controlled loading angles, and engineered securing systems that reduce structural stress. Unlike air freight, where cargo must fit within predefined aircraft constraints, ground logistics allows route-specific planning and tailored movement.

Another critical factor is predictability. Road transport enables pre-surveyed routes that account for bridge load limits, turning radii, overhead clearances, and surface conditions. This precision reduces the risk of transit damage and protects installation timelines at assembly facilities. In aerospace manufacturing, where production schedules are tightly sequenced, that level of reliability is essential.

2. What makes rail transport suitable for aerospace logistics?

Rail transport is suitable for aerospace logistics because it provides stable, long-distance movement with lower vibration impact and strong load-bearing capacity.

Heavy aerospace components such as structural frames, engine modules, or large tooling equipment benefit from rail’s inherent stability. Compared to long-haul trucking over uneven road networks, rail systems offer smoother motion profiles, which helps reduce micro-vibrations that can affect sensitive assemblies.

Rail is also energy efficient and cost effective for cross-country transportation. In integrated ground logistics plans, rail often serves as the backbone for long-distance transit, while specialized trucks manage first-mile and last-mile delivery. This multimodal coordination strengthens supply chain efficiency while keeping transport risks controlled.

For OEMs operating across large geographies, rail becomes a strategic tool to move bulk aerospace cargo reliably while supporting sustainability objectives.

3. How are aerospace parts protected during ground transportation?

Aerospace parts are protected during ground transportation through engineered packaging systems, structural supports, and real-time monitoring technologies.

Protection begins with custom cradles and fixtures designed to match the geometry of the component. These supports distribute weight evenly and prevent stress concentration on sensitive points. Hydraulic trailers with air-ride suspension systems minimize vibration and road shock. For ultra-sensitive equipment, shock absorbers and vibration dampening materials are integrated directly into transport frames.

Environmental control is equally important. Temperature-sensitive avionics or composite materials may require climate-controlled trailers. Moisture barriers, anti-static wrapping, and corrosion protection coatings are applied depending on material type.

Modern logistics solutions also incorporate IoT-based sensor monitoring. These sensors track tilt, shock levels, temperature, and humidity throughout transit. If parameters exceed predefined limits, alerts are triggered immediately, allowing corrective action before damage occurs. This combination of engineering, packaging precision, and digital oversight ensures aerospace-grade protection across the supply chain.

4. Why are permits and escort vehicles required for oversized aerospace loads?

Permits and escort vehicles are required because oversized aerospace components often exceed standard legal limits for width, height, length, or weight on public infrastructure.

Government transport authorities regulate road safety and infrastructure protection. When a shipment surpasses standard dimensions, special permits are mandatory to authorize movement along approved routes. These permits confirm that bridges, tunnels, flyovers, and road surfaces can safely support the load.

Escort vehicles enhance safety by managing traffic flow, guiding turns, and alerting the public to wide or slow-moving cargo. In certain cases, police coordination or temporary road adjustments may be required.

Before movement begins, route surveys are conducted to evaluate obstacles, load capacities, and clearance points. This structured compliance process protects both public safety and the integrity of high-value aerospace components. Without regulatory adherence, shipments risk delays, penalties, or operational disruption within the broader supply chain.

5. How does Triton deliver a precision-focused aerospace logistics solution?

Triton delivers a precision-focused aerospace logistics solution by combining engineering expertise, compliance management, and real-time supply chain visibility.

Each project begins with route engineering and feasibility analysis. Structural fixture designs are developed specifically for the cargo profile, ensuring secure load distribution. Our teams coordinate permits, regulatory documentation, and customs compliance to prevent administrative bottlenecks.

Beyond transportation, we align warehousing, consolidation, and multimodal ground logistics into a unified operational framework. The objective is to support aerospace OEMs with dependable logistics solutions that reinforce supply chain resilience, regulatory compliance, and delivery precision.