By Jitendra Srivastava

Aerospace manufacturing has outgrown the idea of a single factory and a single route. Today, an aircraft fuselage may be fabricated in one country, avionics sourced from another, composites molded somewhere else, and final integration completed thousands of kilometers away. What connects all of it is not just engineering. It is multimodal logistics.

This shift is not cosmetic. It is structural.

According to the Ministry of Civil Aviation, India’s civil aviation sector has been one of the fastest-growing in recent years, with passenger traffic crossing pre-pandemic levels and fleet expansion underway. At the same time, the Department for Promotion of Industry and Internal Trade highlights aerospace and defense manufacturing as priority sectors under national industrial development programs. On the space side, the Indian Space Research Organisation continues to expand launch activities and satellite deployments.

What this really means is simple. Aerospace supply chains are getting deeper, more global, and more time-sensitive. And multimodal logistics is becoming the backbone that holds them together.

Why Aerospace Cannot Rely on One Mode

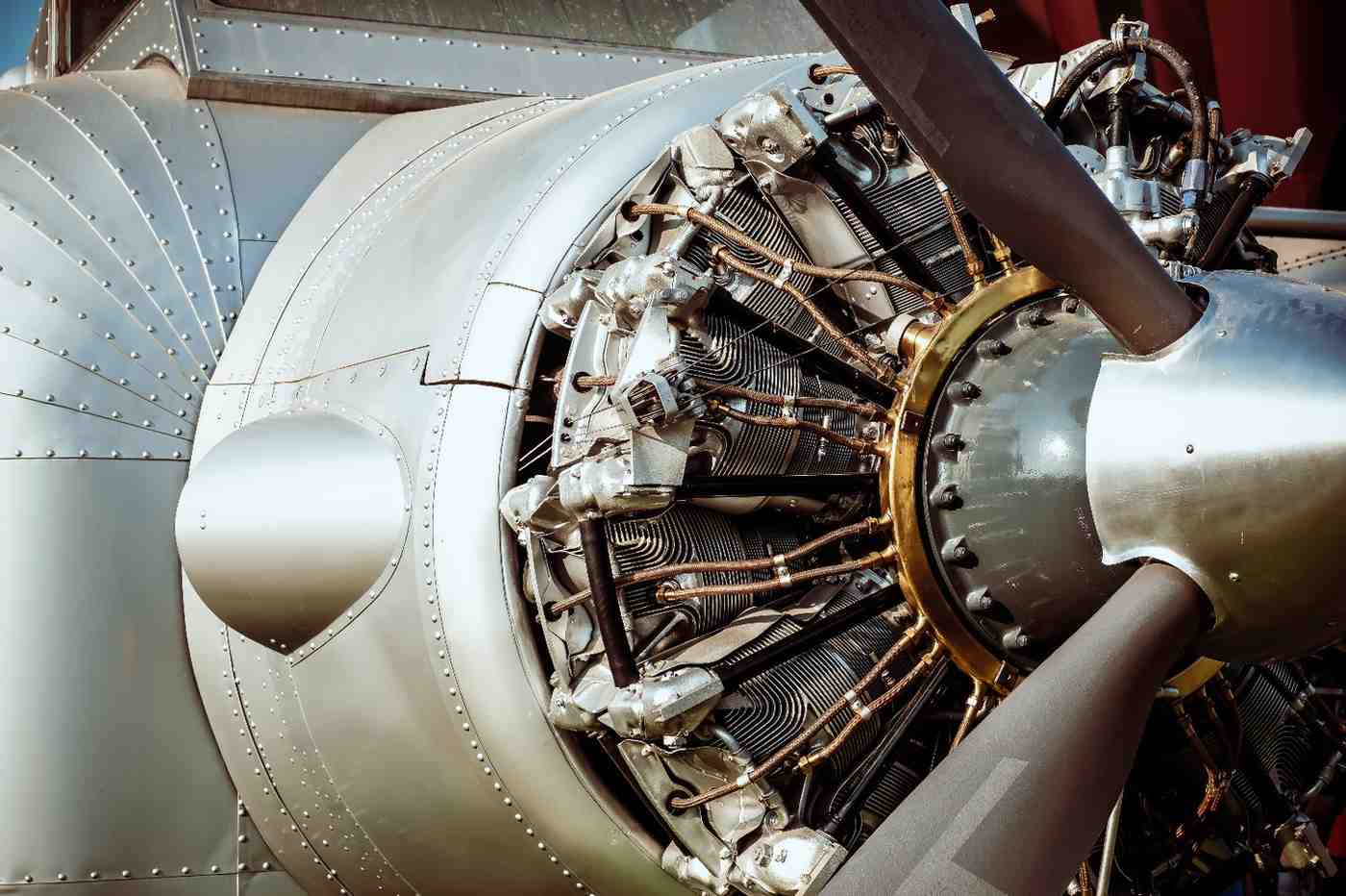

Aerospace programs combine massive structural components with delicate electronics and high-value propulsion systems. Some shipments are oversized. Others are vibration-sensitive. Some are routine. Others are mission-critical.

Relying only on air or only on sea is no longer practical.

Multimodal logistics allows manufacturers to combine road, rail, sea, and air in a planned sequence. Heavy, non-urgent assemblies move by sea. Time-sensitive avionics move by air. Domestic transfers run by road under controlled conditions. The idea is not speed alone. It is optimization.

For aerospace manufacturers, this balance directly affects production timelines and cash flow. For a freight forwarder, it demands deeper coordination than traditional freight forwarding.

How Multimodal Logistics Works in Aerospace

Consider a satellite component manufactured inland. It may first travel by road to a consolidation hub. From there, it moves by sea to a coastal gateway near the integration facility. If final assembly deadlines tighten, the last leg can shift to air.

That flexibility is the essence of multimodal logistics.

Instead of committing to one route months in advance, aerospace planners build decision points into the chain. If weather disrupts sea schedules, cargo can pivot to air. If air capacity tightens, shipments can move earlier by ocean and buffer inventory strategically.

A freight forwarder operating in this environment is not just booking space. They are designing routing architecture across supply chains.

Space and Defense Raise the Stakes

Space systems illustrate this clearly. Rocket stages, propulsion modules, and ground support equipment rarely move in a straight line. They move between fabrication plants, testing facilities, and launch sites.

Recovery operations add another layer. Components retrieved at sea must move by port handling and then road transport to refurbishment centers. Each transition requires planning, permits, and documentation continuity.

Defense logistics demands even higher resilience. Redundant routes, alternate carriers, and strict compliance standards are mandatory. Multimodal logistics allows planners to prequalify alternate corridors rather than scramble during disruption.

The Ministry of Defence, Government of India has consistently emphasized indigenization and domestic manufacturing growth in annual reports. As local production rises, internal multimodal networks become even more critical.

The Role of the Freight Forwarder Has Changed

In aerospace, a freight forwarder cannot be transactional. The responsibility extends beyond freight forwarding into risk mapping.

A capable freight forwarder must:

- Design packaging suitable for sea transport and air handling

- Align documentation across export controls and customs systems

- Maintain real-time visibility across legs

- Provide escalation frameworks for urgent requirements

Freight forwarding in aerospace now overlaps with engineering logic. Packaging design, shock absorption, humidity controls, and route risk assessments are integrated decisions.

That is where multimodal logistics becomes strategic rather than operational.

Technology as the Integrator

Digital tracking systems now allow manufacturers to monitor cargo across modes through a single dashboard. Temperature sensors, shock indicators, and GPS telemetry provide shipment-level visibility.

Government digitization initiatives also support this shift. India’s push toward electronic documentation in customs and port processes reduces clearance time and paperwork duplication. That alignment matters when aerospace parts cross multiple borders.

For supply chains, visibility is no longer optional. It is governance.

Managing Volatility in Air Freight

Air freight remains critical for aerospace. But capacity fluctuates. Global demand spikes, route suspensions, or geopolitical shifts can tighten availability quickly.

A multimodal logistics framework cushions that risk. When air freight rates rise sharply, planned sea-air combinations can protect cost structures. When deadlines compress, pre-negotiated air allocations prevent last-minute chaos.

This layered model reduces exposure to single-mode shocks. And in aerospace, predictability is currency.

Cost, Risk, and Readiness

Let’s break it down.

Multimodal logistics reduces total landed cost by allocating each shipment to the mode that performs best. It also reduces risk by diversifying routes. Most importantly, it protects production schedules.

Aerospace programs cannot afford prolonged idle assembly lines. Every delayed component cascades across teams. Freight forwarding decisions therefore influence engineering outcomes.

That is why logistics service providers in this sector must operate as partners, not vendors.

What Aerospace Leaders Should Demand

When evaluating a freight forwarder for aerospace programs, ask clear questions.

Can they demonstrate experience with multimodal logistics across land, sea, and air?

Do they manage compliance internally or outsource it?

Can they model alternate routes before disruption occurs?

Do they understand aerospace packaging standards?

Freight forwarding in this sector is not about moving boxes. It is about preserving precision.

Final Thought

From hangar floors to orbital launchpads, aerospace manufacturing depends on coordination. Multimodal logistics is the invisible system that keeps those movements synchronized.

As fleet expansion, defense manufacturing, and space missions accelerate, supply chains will only grow more complex. The companies that invest in structured multimodal logistics today will operate with tighter timelines, lower risk, and stronger readiness tomorrow.

For aerospace leaders, the question is no longer whether to adopt multimodal logistics. The real question is how intelligently it is designed.

FAQs

1. Why is multimodal logistics essential in aerospace manufacturing?

Aerospace supply chains involve global sourcing of large and delicate components. Multimodal logistics allows manufacturers to combine sea, road, and air freight strategically, balancing cost, speed, and risk while protecting production timelines.

2. How does a freight forwarder support aerospace projects?

A freight forwarder coordinates routing, documentation, packaging standards, and compliance across modes. In aerospace, freight forwarding also includes risk assessment, visibility integration, and contingency planning.

3. What challenges arise in multimodal aerospace logistics?

Regulatory complexity, export controls, environmental handling requirements, and air freight volatility are key challenges. Strong process governance and integrated tracking systems help manage these risks.

4. How does multimodal logistics reduce cost without increasing delay?

By allocating heavy cargo to sea, urgent cargo to air, and domestic transfers to road, multimodal logistics optimizes each leg. This reduces overall freight expenses while maintaining schedule discipline across supply chains.