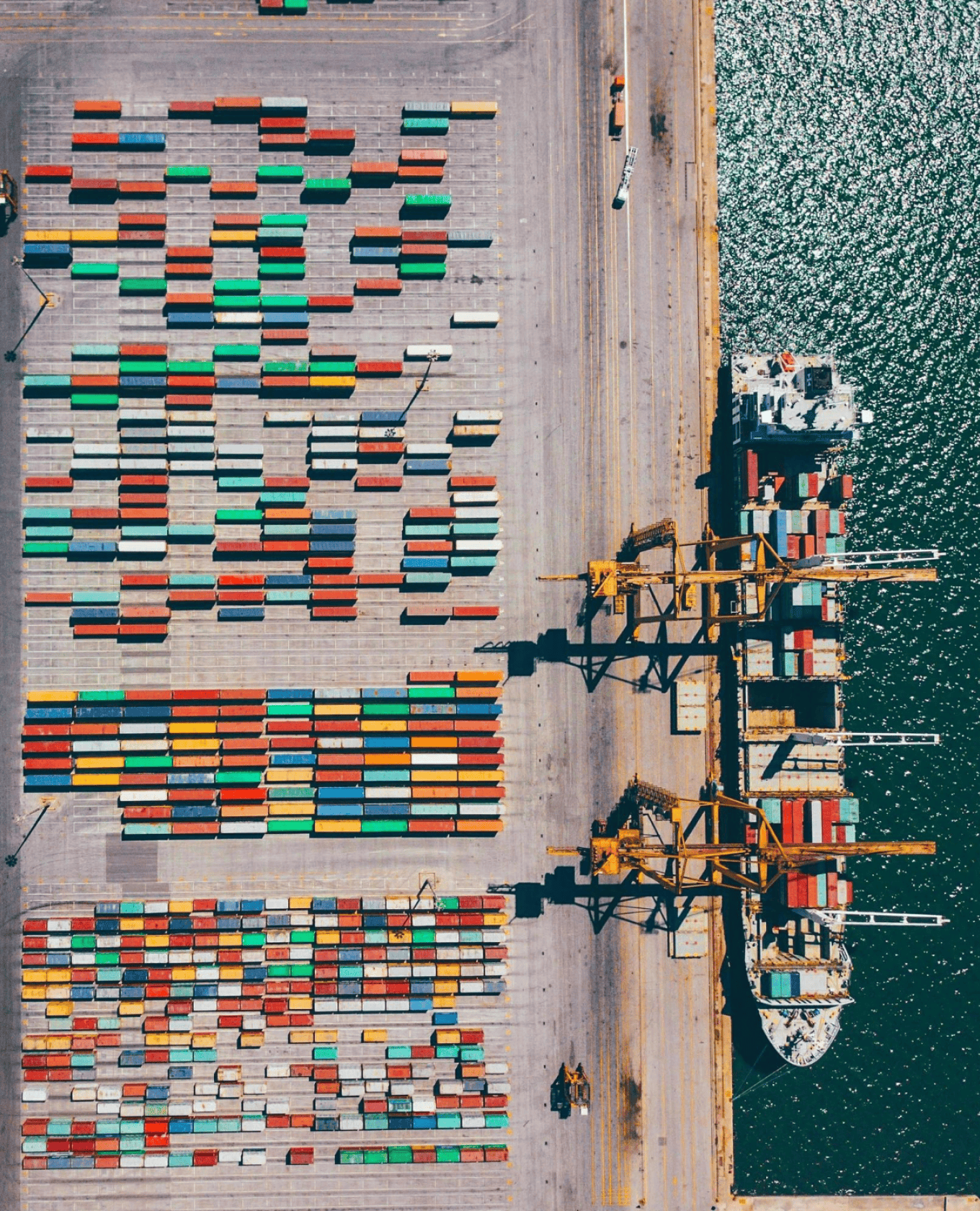

In EPC logistics, every late shipment carries a price tag: not only in lost time but often in millions of dollars in penalties. Precision is vital for big infrastructure projects in the Engineering, Procurement and Construction (EPC) field. Every deadline and delivery is important. Yet, even with strict tender clauses and detailed schedules, delays are frequent. When penalties kick in, they can wipe out margins and even put the financial viability of a project at risk.

But what exactly makes these delays so expensive? And how can project owners design better tenders, evaluate bids more carefully, and craft smarter contracts to stop them before they put the whole timeline at risk?

The Cost of Delays in Projects

In EPC logistics, even minor time overruns usually disrupt other operations. Work on the site slows down when tools and materials don’t arrive on time. When resources lie idle, deadlines are missed, and penalty clauses kick in. In many cases, liquidated damages can exceed the estimated revenues from a project.

For example, consider a large petrochemical project that required heavy offshore compressors and subsea pipe-laying equipment. Shipments were delayed at sea, which meant installation windows in calm waters were missed. The delay added months to the project timeline. It led to penalties that ran into tens of millions of dollars, throwing the contractor’s financial model off balance.

The lesson is clear: in EPC, logistics delays are not minor inconveniences. They can put entire value chains at risk.

What We Learned from Late Contracts

1. Not realizing how complicated the supply chain is

Many EPC projects depend on worldwide sourcing, multimodal transport, and multiple vendors. A delay in customs clearance at one port can set off a chain reaction. Tender documents that do not clearly address risk allocation, delivery commitments, and responsibility for delays leave projects exposed.

2. Not enough due diligence on vendors

A frequent pitfall is selecting vendors solely based on cost. In one instance, a freight forwarder that had not been thoroughly vetted encountered financial difficulties during execution. This resulted in shipment delays and a considerable loss of time.

Here, tender management is critical: bid evaluation must go beyond lowest cost and include checks on financial health, compliance with safety requirements, and proven EPC logistics experience. Only a structured, data-driven process within tendering can filter out unreliable freight forwarders and logistics service providers.

3. Unclear Roles and Duties

Not being clear about who is responsible is a common cause of disputes. Delays are more likely when contracts don’t spell out the responsibilities of each party, such as sub-suppliers and last-mile providers. Tender clauses must assign accountability upfront; otherwise, penalty provisions only add cost without fixing the root cause.

The Freight Forwarder’s Role in Tender Management

Freight forwarders often decide whether an EPC project stays on track or stalls. Yet in many tenders, their role is bundled under generic logistics services rather than being treated as a critical partner.

A well-chosen freight forwarder can coordinate multimodal transport, anticipate customs delays, and secure capacity in advance.

A poorly vetted one can collapse under financial strain or operational complexity, dragging the entire supply chain down.

Tender design should therefore dedicate specific evaluation criteria to freight forwarders, looking at past EPC track records, risk management systems, and ability to provide real-time visibility. Elevating them from an afterthought to a defined contract partner reduces exposure to cascading delays.

The Importance of Proactive Risk Assessments

Identifying risks early

Good tender management begins before a contract is signed. You must account for customs delays, worker strikes, bad weather, and political instability. By planning for these risks, you may write stronger clauses and establish timetables that can handle them.

Scenario planning and buffer times

Best-case scenarios rarely play out in EPC logistics services. It is important to build buffer times, alternate routes, and contingency capacity into tender documents. These measures keep projects moving even when problems like port congestion or a vendor bankruptcy occur.

Tools for digital transparency

Modern technology adds protection. Real-time tracking, automated alerts, and dashboard reporting highlight risks before they worsen. Embedding such tools into tender requirements ensures that logistics service providers remain accountable and proactive.

Making Penalty Clauses Work

Connecting Clauses to Realistic Milestones

Penalty clauses are helpful only when tied to realistic milestones. Tender management must align delivery goals with actual logistics capabilities, reducing disputes and inflated claims.

Adaptability for Force Majeure

You need flexibility for events beyond your control, such as natural disasters or political upheaval. Well-drafted tender clauses define delay limits, remedies, and exceptions, balancing protection with fairness.

Transparency in Action

As part of a large transportation infrastructure project, shared risk assessments were included in the tender. When bad weather delayed shipments, contingency plans were activated and no penalties were imposed. The project advanced while trust was maintained.

Common Mistakes in Tender Management

- Rushing the process: Tight bid windows often lead to vague timetables and incomplete risk provisions. Detailed tender drafting prevents this.

- Ignoring monitoring: Signing the contract is only the first step. Tender frameworks should require ongoing reporting and audits to catch problems early.

- Chasing the lowest price: Choosing the cheapest freight forwarder may save money upfront but usually costs more later in delays and disputes. Structured evaluation in tender management ensures long-term reliability.

In Conclusion: Making EPC Logistics More Reliable

Delays and fines do not have to plague EPC projects. With robust tender management, careful vendor evaluation, and active monitoring, projects can finish on time and within budget.

At Triton Maritime and Logistics, we combine expertise in tender design with proven logistics service execution. Our goal is to help EPC clients identify risks early, avoid costly mistakes, and turn their tendering process into a competitive advantage.

It is simple: prepare ahead today to avoid penalties tomorrow. Partner with us to keep your next EPC project on track at every level.